Din 650 T Slot Dimensions

T-slot cutters with Morse taper shanks; dimensions (FOREIGN STANDARD)

- Din 650 T Slot Dimensions Comparison

- Din 650 T Slot Dimensions Pdf

- Din 650 T Slot Dimensions Guide

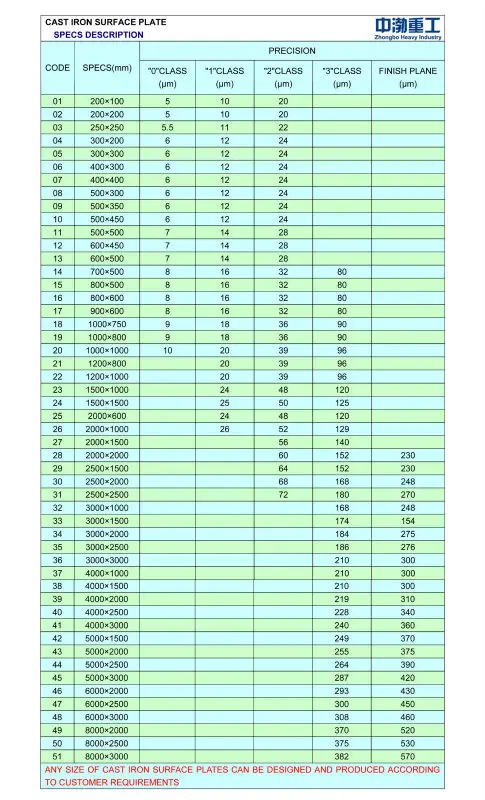

- Din 650 T Slot Dimensions Chart

The standard specifies the dimensions and designation for T-slot cutters with morse taper shank used mainly for making T-slot according to DIN 650. Further information, d.g. on material, design and marking, is given in DIN 851 part 3 technical delivery conditions.

Content Provider

Deutsches Institut für Normung [DIN]

Your Alert Profile lists the documents that will be monitored. If the document is revised or amended, you will be notified by email. You may delete a document from your Alert Profile at any time. To add a document to your Profile Alert, search for the document and click “alert me”.

When a unit is referred to as a single DIN car stereo, or a single DIN car radio, that means it is the height and width outlined in the DIN standard. Automakers and car stereo manufacturers around the world use this standard, which is why most head units are interchangeable. (t) 6 8 2 1.0 2 2 9 10 3 1.4 3 3 11 12 4 1.8 4 4 13 17 5 2.3 5 5 18 22 6 2.8 6 6 23 30 8 3.3 8 7 31 38 10 3.3 10 8 39 44 12 3.3 12 8 45 50 14 3.8 14 9 51 58 16 4.3 16 10 59 65 18 4.4 18 11 66 75 20 4.9 20 12 76 86 22 5.4 22 14 86 96 25 5.4 25 14 96 110 28 6.4 28 16 111 130 32 7.4 32 18 131 150 36 8.4 36 20 151 170 40 9.4 40 22 171 200 45 10.4 45 25. Here you can find our T-slot plates produced from steel and cast aluminum, and accessories such as clamps and T-slot nuts. Cast aluminum T-slot plates: Tolerance/Precision: +/- 0.01 mm /200 mm Steel (C45) T-slot plates: Tolerance/Precision: +/- 0.05 mm /200 mm Steel (C45) T-slot plates (shaped finely): Tolerance/Precision: +/- 0.01 mm /200 mm. Die size 2 Allocation of Die length in rolling direction Cross-over zone A ROLLBLOC die lifters with spring pressure Multi-part allocation of one T-slot CT-SLOT 18, DIN 650 Order code D18. CRECTANGULAR SLOT 18x30 Order code D18. 14 Allocation planning (examples) Die size 2 1 2.

Please first verify your email before subscribing to alerts.Your Alert Profile lists the documents that will be monitored. If the document is revised or amended, you will be notified by email. You may delete a document from your Alert Profile at any time. To add a document to your Profile Alert, search for the document and click “alert me”.

Already Subscribed to this document.Your Alert Profile lists the documents that will be monitored. If the document is revised or amended, you will be notified by email. You may delete a document from your Alert Profile at any time. To add a document to your Profile Alert, search for the document and click “alert me”.

What are DIN rails?

DIN rails are the long metal strips that form the core part of a global industry standard component rail-mounting system in equipment cabinet racks. DIN rails are designed for securely attaching electrical and industrial control products - such as circuit breakers, terminal blocks, power supplies, actuators, solenoids and so on - inside a typical equipment rack housing cabinet or frame.

In this context, ‘DIN’ is an acronym that stands for Deutsche Institut für Normung, which translates into English as ‘German Institute of Standards’. The now-familiar rack-mounting system we see supporting components of all kinds in many industrial settings was first devised by the Germans in the late 1920s. It was more widely adopted and developed into its current form during the 1950s, initially by neighbouring European countries and then quite quickly taken up worldwide.

DIN rails exist purely for the purpose of physical (mechanical) component support, rather than as any sort of connective or conductive element within a wider electrical system. In other words, they are not busbars, although they can perform a grounding busbar role in certain scenarios.

Din 650 T Slot Dimensions Comparison

The advantages of a DIN rail system for mounting hardware components are numerous:

Din 650 T Slot Dimensions Pdf

- They save time and work - components simply snap or slide into place on the rail, rather than having to panel mount each individual component separately.

- They save space - DIN rails allow for tight configurations of components and provide a convenient site for bringing internal and external wiring circuits together, ideal in limited space applications

- They’re cost-effective, both in terms of DIN rail pricing itself and the potential it offers for high-density adjacent mounting - this can significantly reduce the overall amount of wiring and cabinet space needed

- They promote neat and well-organised component layout, which is better for all-round safety and maintenance access

- They adhere to universal sizing and mounting protocols - see below

Din 650 T Slot Dimensions Guide

The real beauty of the DIN rail system is that it was designed (and has continually evolved) to work with to a series of universal standard widths and shapes of mounting hardware. The fact that DIN rail systems are today recognised as a range of fixed and consistent standards means that installers can be guaranteed dimensional uniformity across a whole suite of relevant products, regardless of whichever company is handling manufacture or supply of various individual parts.

Din 650 T Slot Dimensions Chart

This level of cross-brand compatibility gives users of DIN rail systems the flexibility to mix and match components, without having to stick to a single proprietary model range to get the job done. Proprietary systems do exist, but they’re less widely used for precisely this reason.